Assurance of food safety

As a food company, we at the Calbee Group believe that providing safe and reliable products is one of our most important social responsibilities. We conduct thorough quality management in compliance with FSSC 22000, an international standard for food safety system certification, to strengthen our systems for quality assurance across the entire value chain, from production to customers. Moreover, we will always pay attention to our customers' voices, use their suggestions to make improvements, and communicate our responses so as to boost the customers’ motivation to repeatedly purchase our products as part of the Group’s united endeavor to offer products that win the trust of, and offer satisfaction to, customers.

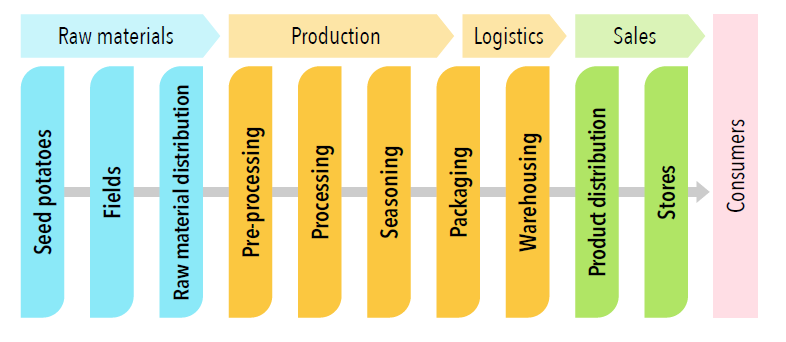

Quality assurance system that supports the value chain

Calbee’s unique 10 Processes value chain sets forth standards to ensure that each process guarantees 100% quality to the subsequent process. The linking of these processes enables us to achieve full quality assurance of all products and provide traceability for our customers.

Prevention of safety and quality incidents and monitoring

Acquisition of the international standard FSSC22000 certification and compliance

Based on the international standard for food safety management systems, FSSC 22000, we use the HACCP approach to analyze hazards, determine management methods, and confirm operations through internal and periodic audits. When introducing new equipment, we prevent risks from materializing by inspecting the manufacturing floor and carrying out hazard analysis in advance. Thirteen Calbee Group factories in Japan have obtained the FSSC22000 certification.

AAO activities (anshin [safe], anzen [reliable], and oishii [delicious])

There have been product contamination incidents at Calbee in the past, which required us to carry out large-scale product recalls. To ensure that these mistakes are not forgotten or repeated, we conduct a group-wide activity every year to improve quality, allowing us to continue offering customers products that are safe (anzen), reliable (anshin), and delicious (oishii). In this activity, we raise our employees’ awareness of food quality and safety by reflecting on past product recalls, listening to customer feedback, and reaffirming the purpose of our food safety rules.

Ensuring the safety of raw materials

Calbee procures and utilizes a range of raw materials, including potatoes, shrimp, and oats. We have established standards for all raw materials we use and ensure thorough safety control based on the quality specifications of these raw materials. We screen all new raw material candidates for risks at their production sites and determine whether or not to adopt them.

-

-Residual pesticides: We manage the safety of raw materials through appropriate pesticide management at farms and residual pesticide inspection according to our own standards in compliance with laws and regulations.

-

-Allergens: We thoroughly clean our production lines at factories to ensure that our products do not become contaminated with allergens.

Strengthening quality control and inspection in the manufacturing process

We have taken various initiatives to ensure that the products we provide to our customers are safe and reliable. These initiatives include setting up X-ray inspection devices, metal detectors, and surveillance cameras at our manufacturing sites to prevent contamination with foreign substances.

In product quality inspection, we have introduced a system to enable the acquisition of physicochemical inspection data in real-time by installing near-infrared cameras on the production lines of some factories.

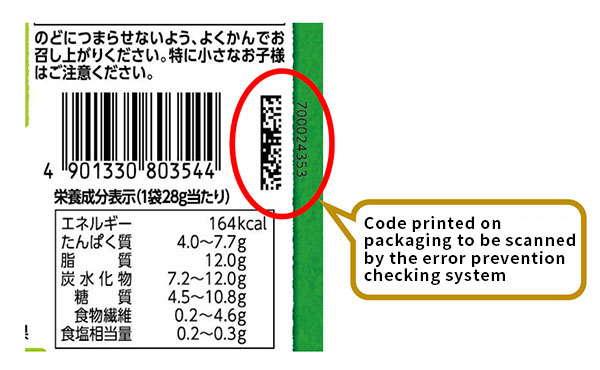

In the packaging processes on our production lines, we have introduced an error prevention matching system that checks whether the product contents match the packaging film to prevent errors in ingredient labels.

Error prevention checking system

Quality assurance training

We organize regular workshops on labeling requirements, raw material specifications, and product specifications and standards for product planning and development staff every year. At our factories, we offer a training program to quality assurance managers who will lead the next generation. They, in turn, share that knowledge and information with other employees on the manufacturing floor. We also hold study sessions with external lecturers specialized in quality assurance to acquire new knowledge.

Quality assurance management of overseas group companies

The Quality Assurance Division is working together with the overseas divisions to enhance the quality control systems at overseas group companies and factories of alliance partners. We conduct food sanitation audits at overseas group company factories based on the Calbee Group Food Hygiene Standard and instruct them to maintain high hygiene standards. Moreover, we have quality assurance systems that comply with local requirements, as each country has its own specifications and standards, including import and export regulations and package labeling requirements.

Initiatives for ensuring safety

Provision of information on food allergies, etc.

Information such as allergens related to products, ingredients, and nutritional facts has been made available on the Product page of the Calbee website since November 2024.

Compliance with laws and regulations governing information provided on social media

Stealth marketing was banned under the Act against Unjustifiable Premiums and Misleading Representations in October 2023. To ensure compliance with the law, Calbee has established a verification system and strives to conduct fair advertising and promotion, ensuring that customers are not harmed by stealth marketing or affiliate advertising.