Promoting a recycling society

The Calbee Group strives to create a recycling society and is committed to reducing food waste, conserving water resources, and promoting waste reduction and recycling.

Main initiatives

Reducing product food loss

The Calbee Group has set a target to reduce product food loss by 30% (compared to the three-year moving average for the fiscal year ended March 31, 2023) by the fiscal year ending March 31, 2031. As a result of these initiatives, food loss reduction for the fiscal year ended March 31, 2025, averaged 6.1%.

In order to achieve our targets, the Calbee Group is implementing improvement activities such as inspection of work procedures and equipment and introduction of new equipment in the manufacturing process.In addition, because many product food losses may occur due to a single problem, improvement activities are shared at meetings attended by production section managers at each plant.

Reducing water consumption

We have set a target to reduce water consumption by 10% (compared to the fiscal year ended March 31, 2019) by the fiscal year ending March 31, 2031. However, consumption rose by 4.5% in the fiscal year ended March 31, 2025. This was due to an increase in the water used to wash potatoes, our primary ingredient, as well as an increase in water consumption resulting from the opening of a new factory.

In the future, the Drainage Management Committee, comprised of persons in charge at each factory, will play a central role in striving to optimize water consumption and promote recycling, especially with regard to potato chips, JagaRico, for which the amount of water consumption is high, and take measures surrounding the production of this product.

Waste reduction

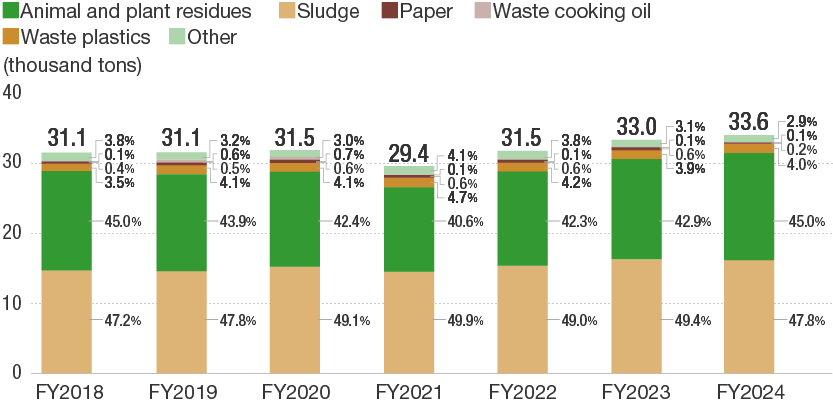

We have set a target of reducing waste emissions by 10% (compared to the fiscal year ended March 31, 2019) by the fiscal year ending March 31, 2031, but results for the fiscal year ended March 31, 2025, showed an increase by 8.0% due to poor quality of raw materials and increased production.

The first priority of the Calbee Group is to produce products that conform to quality standards and to prevent losses.We are striving to reduce waste by reducing the volume of waste generated in the production process through drying, etc., and reusing it as a high-value-added resource (turning it into valuable resources). Regarding sludge, animal and plant residues*, and waste plastics, which are particularly high in emissions, the internal Waste Committee will lead the implementation and continuation of these initiatives.

* Collectively refers to potato peels and scraps that cannot be used in products.

Changes in total waste volume over time