Achieving carbon neutrality

Record-breaking heatwaves, torrential rains, and droughts have occurred frequently on a global scale in recent years. Natural disasters caused by climate change are posing a more serious threat to Japan as well. For this reason, people around the world are becoming increasingly aware of the need to reduce greenhouse gas emissions, which are considered a major contributor to climate change. Addressing global warming caused by climate change is an urgent issue for the Calbee Group, which values and makes the most of nature’s bounty.

Calbee has set a target (KPI) to reduce total greenhouse gas emissions by 30% (compared to the fiscal year ended March 31, 2019) by 2030 and is moving forward accordingly.

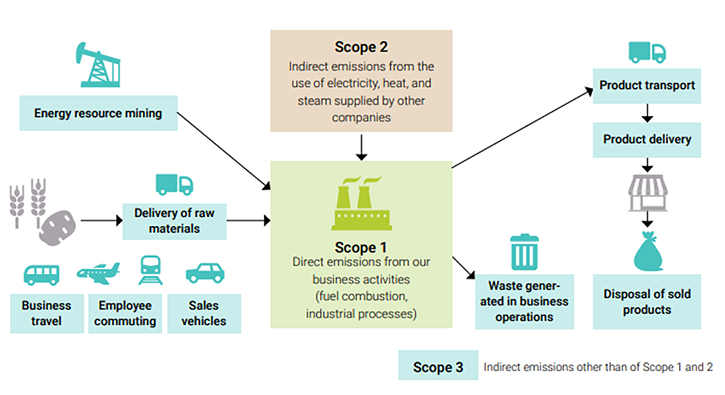

We are promoting energy-saving activities and using renewable energy to reduce our Scope 1 and 2 emissions. We are strengthening our engagement with suppliers to address the reduction of our Scope 3 Category 1 emissions, which is challenging to achieve without their cooperation. In line with these activities, we will set targets and reduce them.

Energy savings through a smart energy project in the Kiyohara Industrial Park

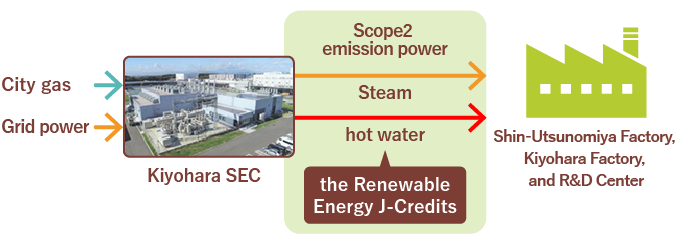

Three Calbee business locations, namely, Shin-Utsunomiya Factory, Kiyohara Factory, and the R&D Center, have been participating in a smart energy project in collaboration with neighboring companies since February 2020. The smart energy project uses energy efficiently through the Kiyohara Smart Energy Center (hereinafter, Kiyohara SEC) established in the Kiyohara Industrial Park in Utsunomiya City, Tochigi Prefecture.

With this project, energy demand can be monitored in real-time based on information such as outdoor conditions, which change daily, the status of energy use in each factory, and the operational status of heat source equipment. By supplying heat and electricity produced at Kiyohara SEC to each factory according to demand, we aim to conserve energy and reduce greenhouse gas emissions for the entire industrial park. Significant results, which Calbee could not achieve alone, are made possible through collaboration with the local community and fellow companies.

Kiyohara Industrial Park

Initiatives related to the smart energy project

Carbon offsetting of thermal energy Calbee, Inc. and Tokyo Gas Engineering Solutions Corporation have commenced efforts to reduce Calbee’s CO2 emissions from thermal energy, necessary for its production process, to net zero at Calbee’s three business locations participating in the smart energy project (Shin-Utsunomiya Factory, Kiyohara Factory, and R&D Center) located within Kiyohara Industrial Park, using the Renewable Energy J-Credit Scheme*1. Calbee has been using electricity generated from renewable energy at its factories throughout Japan, but this is the first-ever attempt to offset its CO2 emissions from thermal (steam/hot water) energy. J-credit is allocated to offset CO2 emissions from heat (steam/hot water) supplied from Kiyohara SEC to Calbee's three business locations.

*1 A scheme in which CO2 emissions reduced through the use of renewable energy are certified as credits by the Japanese government (from the Ministry of Economy, Trade and Industry website)

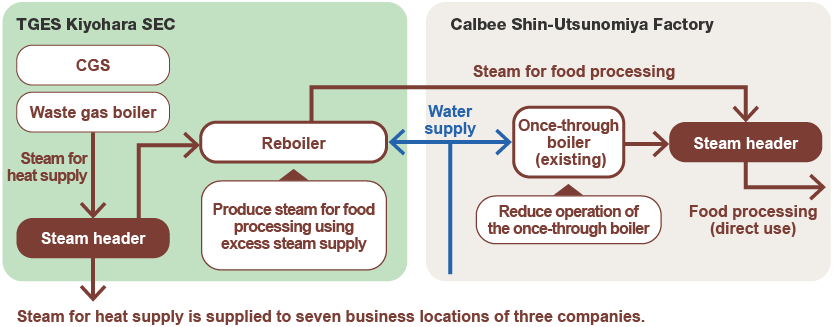

Use of steam generated from waste heat

At the Calbee Shin-Utsunomiya Factory, we formerly produced and used steam that comes in direct contact with food products in boilers fueled by municipal gas. In FY2022, we introduced reboilers at the Kiyohara Smart Energy Center as part of the smart energy project. The reboilers utilize steam generated from waste heat to produce steam for food processing, thereby reducing municipal gas consumption.

Use of renewable energy

Since the fiscal year ended on March 31, 2020, we have been transitioning from purchasing conventional fossil fuel-generated electricity to electricity with non-fossil fuel energy certificates (renewable energy designation)*2, as well as purchasing electricity from solar power generation, among other measures.

Currently, 11 factories purchase and utilize electricity generated from renewable energy sources. Reduction in greenhouse gas emissions resulting from this initiative is equivalent to approximately 44,000 tons of CO2 annually.

*2 A system in which certificates for the non-fossil value of electricity generated using non-fossil fuels, instead of with fossil fuels such as petroleum and coal, are issued and sold. (Source: The Agency for Natural Resources and Energy’s website)

Factories using renewable energy

| Start of usage | Factory name |

|---|---|

| 2020 | Shimotsuma Factory, JFL Koga, Hokkaido |

| 2021 | Kagoshima, Gifu Kakamigahara, Kansai Biwako, Kyoto, Hiroshima Miyajima, Hiroshima Hatsukaichi |

| 2024 | Obihiro |

| 2025 | Setouchi Hiroshima |

Introduction of solar power generation system

Solar power generation systems were installed on top of the Kyoto Factory and Setouchi-Hiroshima Factory to generate electricity using solar panels. The reduction in emissions is equivalent to 259 tons of CO2 annually.

Solar panels

Solar power generation system

Scope 3 emissions reduction

Initiatives with contract potato growers

We conduct interviews with contract potato growers to confirm the amount of fertilizer and pesticides used in the cultivation process, as well as the fuel used in farm equipment. A partial calculation is then made of greenhouse gas (GHG) emissions for each contract grower. While increasing the number of contract growers, for which calculations are made, we are also moving forward with efforts to reduce emissions. This includes collecting and examining information regarding fuel as the primary source of emissions, as well as exploring the possibility of using new fuels in farm equipment.

Initiatives with suppliers: strengthening engagement

To reduce Scope 3 emissions related to raw materials such as film and cardboard, it is essential to obtain primary data from suppliers. Therefore, we have requested cooperation from some suppliers in calculating GHG emissions, including not only Scope 1 and Scope 2 but also Scope 3. We will collaborate with suppliers to implement activities that reduce GHG emissions and have them share the effects and results as primary data as we proceed with reducing Calbee’s Scope 3 emissions.

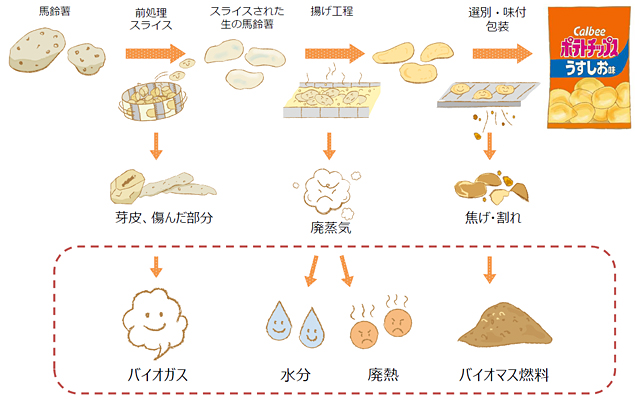

Initiatives at the Setouchi Hiroshima Factory, which commenced operations in January 2025 - An energy system that makes full use of potatoes

Potato residue will undergo methane fermentation, and the resulting biogas will be used to generate steam for use in the factory

In the production process, sprouts, peels, damaged parts, and other potato residues are generated, which are usually discarded; however, factories regard them as valuable resources. Potato sprouts, peels, and damaged sections undergo methane fermentation, and the resulting biogas is used to generate steam. Steam is an essential energy source in the food manufacturing process, and greenhouse gas emissions are being reduced by using biogas to generate it.

Recovering waste steam generated during potato frying by decomposing it into water and heat

Steam generated during the frying process of potato chips was previously treated as waste steam. We have introduced a system that treats this waste steam as a resource, recovering and reusing it. The generated waste steam is recovered and decomposed into water and heat. The recovered water is used for washing potatoes, and the heat is reused to generate hot water.

Utilizing semi-finished product losses (burnt/broken pieces) as biomass fuel to supply CO2-free steam (planned for future implementation)